Processing capacity:16-744TPH

Feeding size:30mm--460mm

Crushing material:Limestone, Granite, Gabbro, Basalt, River Stone, Coal Gangue, Quartz, Diabase,Iron Ore, Copper Ore, Zinc Ore, Manganese Ore, etc. (for Hard Stone).

Applied field:Aggregates Shaping, Mechanism sand, Bituminous Concrete,Metal Mine, Chemical, Road, Railway,Metallurgy, Construction, Highway, Water Conservancy

Introduction:Hydraulic cone crusher is suitable for crushing all sorts of ores and rocks whick is medium or above medium hardness. Compare with jaw crusher, cone crusher is high efficiency, easy adjustment, economic operation and has stable structure, etc.It is widely used in metallurgical industry, hydro-dam construction, transportation, chemical industry and building materials.

Advantages of Hydraulic Cone Crusher:

1. High crushing ratio and production efficiency

The high turning speed and stroke of a hydraulic cone crusher generates greater power and this helps the machine to pass the material at an excellent speed. So eventually it delivers a high production and crushing rate.

2. High quality product shape output

A hydraulic cone crusher uses the method of pressuring two surface layers to crush objects and has adjustable turning speed. A hydraulic cone crusher can selectively smash objects while crushing and this can help increasing the quality output of fine objects and cubic shaped objects as wishes.

3. Automatic discharging

The bidirectional metal releasing part of a hydraulic cone crusher automatically adjusts and discharges the bulk while crushing. So there is no need to halt the crushing process and clean the objects manually.

4. Thin oil lubrication system

The thin oil lubrication system of a hydraulic cone crusher plays a very important role in increasing the life of a crusher. This further helps in making the production process cost efficient.

Multi-cylinder hydraulic cone crusher:

| Model | Cavity | Standard Type | Short Type | Power | Capacity (t/h) | ||

| Feeding Size (mm) | Min Discharging Size (mm) | Feeding Size (mm) | Min Discharging Size (mm) | (kw) | |||

| XHP200 | Super coarse | 132-200 | 90-250 | ||||

| Coarse | 185 | 19 | 76 | 10 | |||

| Medium | 125 | 17 | 54 | 6 | |||

| Fine | 95 | 13 | 23 | 6 | |||

| Super Fine | 10 | 5 | |||||

| XHP300 | Super coarse | 230 | 25 | 180-250 | 115-440 | ||

| Coarse | 210 | 20 | 75 | 10 | |||

| Medium | 150 | 15 | 50 | 8 | |||

| Fine | 105 | 10 | 20 | 6 | |||

| Super Fine | 20 | 6 | |||||

| XHP400 | Super coarse | 295 | 30 | 280-355 | 140-630 | ||

| Coarse | 250 | 25 | 90 | 10 | |||

| Medium | 195 | 20 | 50 | 8 | |||

| Fine | 110 | 14 | 40 | 6 | |||

| Super Fine | 30 | 6 | |||||

| XHP500 | Super coarse | 330 | 30 | 355-450 | 175-790 | ||

| Coarse | 285 | 25 | 90 | 13 | |||

| Medium | 200 | 20 | 55 | 10 | |||

| Fine | 133 | 16 | 40 | 8 | |||

| Super Fine | 35 | 6 | |||||

Single cylinder hydraulic cone crusher specification:

| Model | DP-100 | DP-160 | DP-250 | DP-300 | |

| Motor power(kw) | 75-90 | 110-160 | 132-250 | 200-315 | |

| Stroke(mm) | 16、20、25 | 18、25、32、40 | 18、25、32、40 | 18、25、32、40 | |

| Weight (T) | 9.8 | 12.8 | 23.2 | 38.5 | |

| Max feeding size(mm) | Medium Coarse Extra coarse | 200 250 | 250 330 | 280 380 | 380 500 |

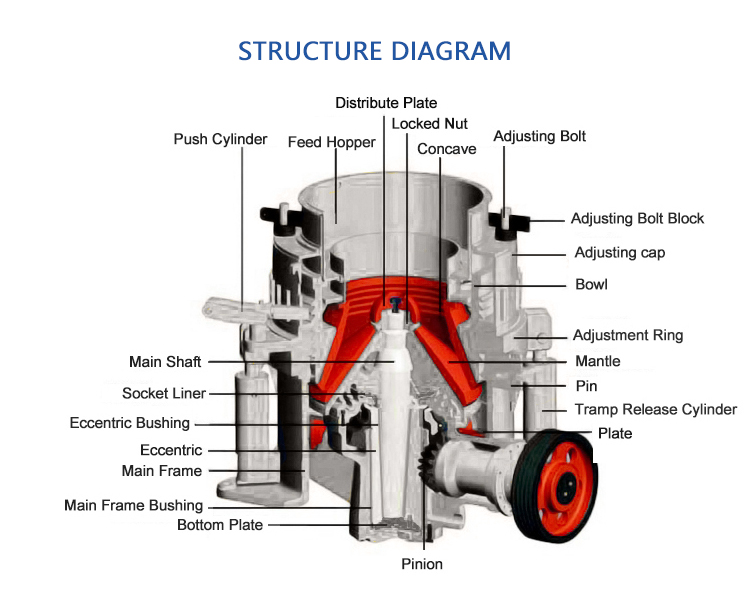

Working Principles of Hydraulic Cone Crusher

The crushing principle of hydraulic cone crusher machine is finished between fixed cone plate and movable cone plate. The motor drives the horizontal axis of the crusher machine through triangle belt and pulley, the horizontal axis drive the eccentric shaft bush to rotate through gear transmission. The eccentric shaft drives the main shaft to make the movable cone plate swing at a regulated track from time to time, the materials are crushed due to constant pressed and crooked in the crushing cavity. The finished products are discharged from the discharging opening.